FIRST Tech Challenge '22-'23 Robot

Summary

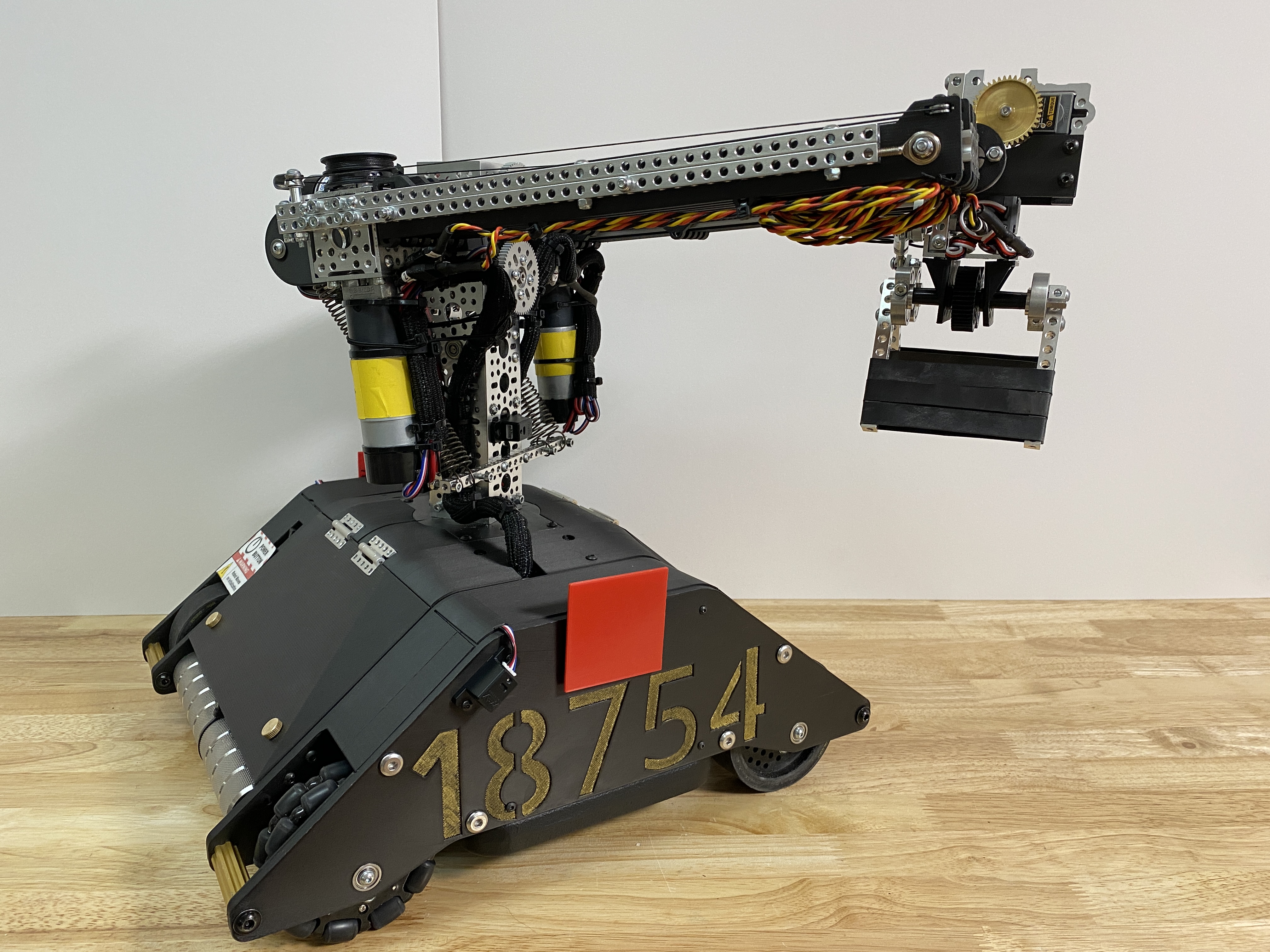

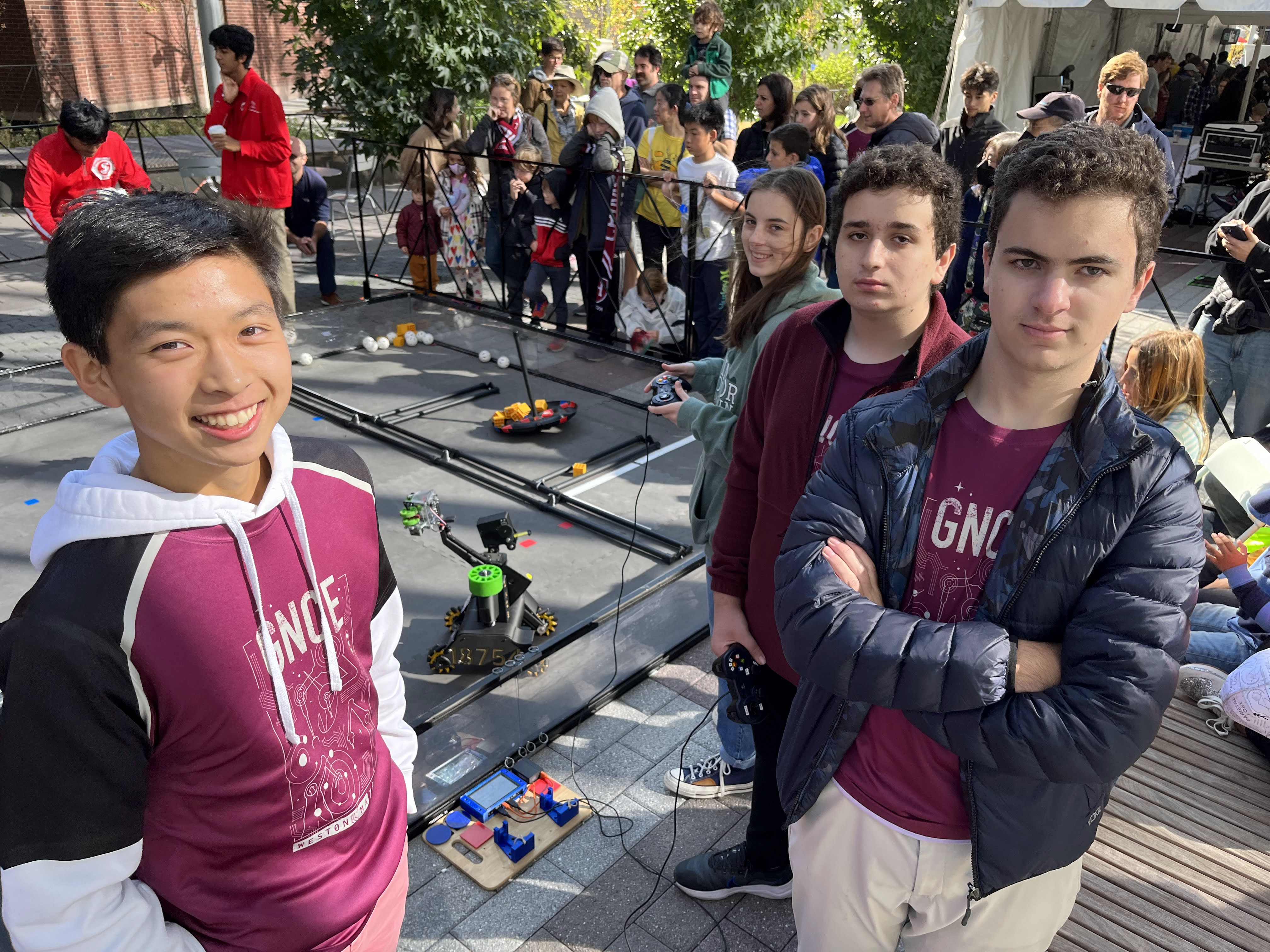

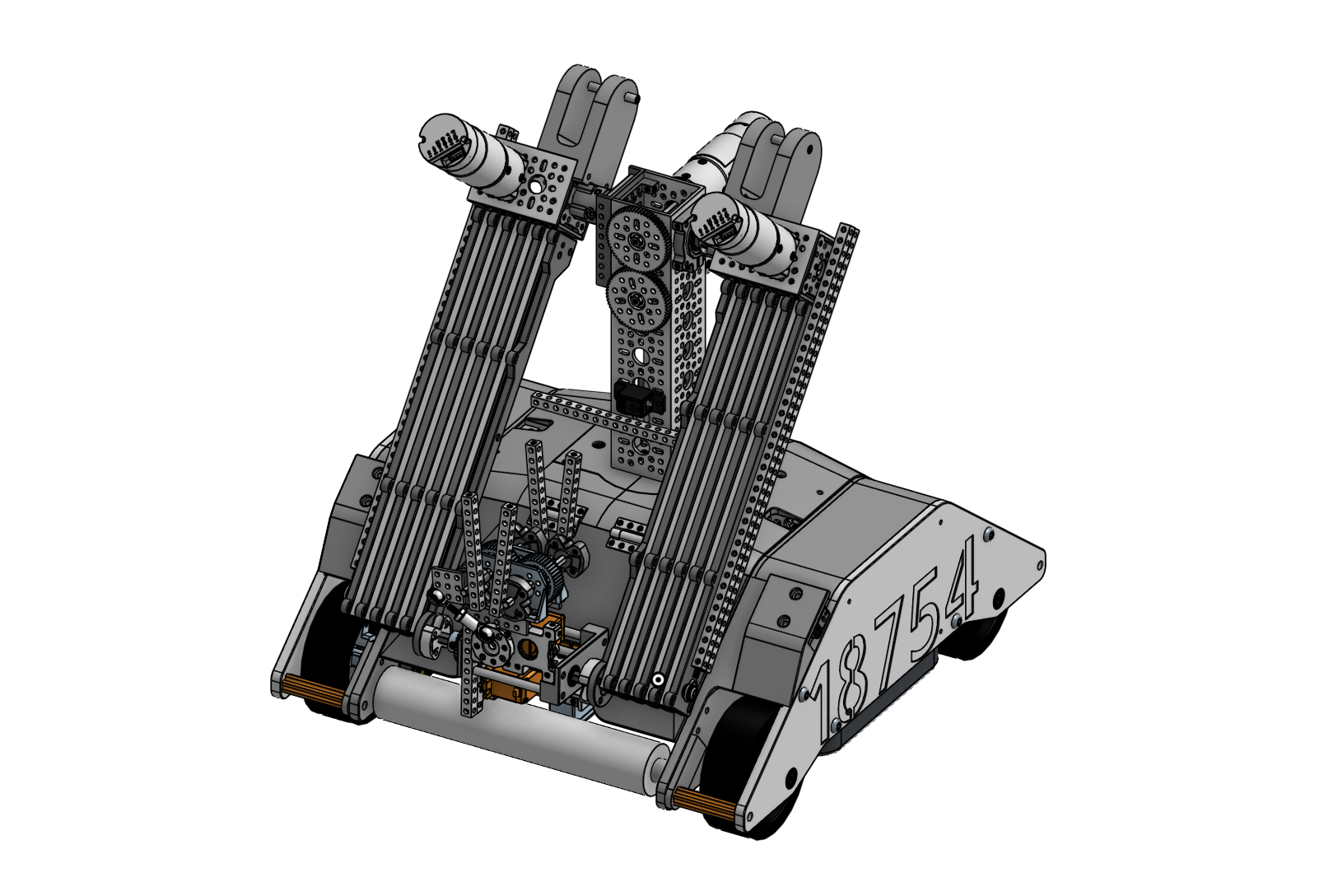

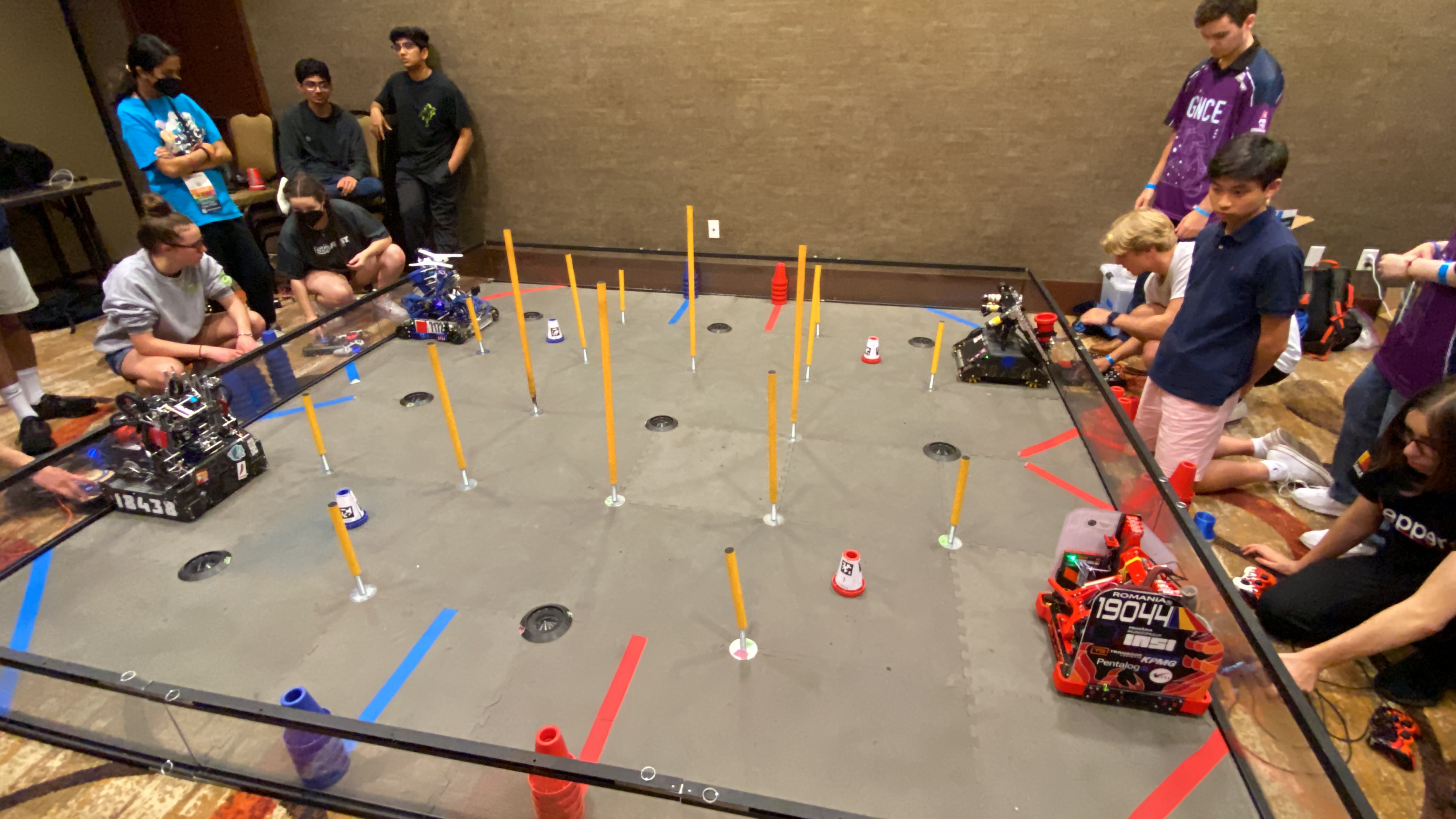

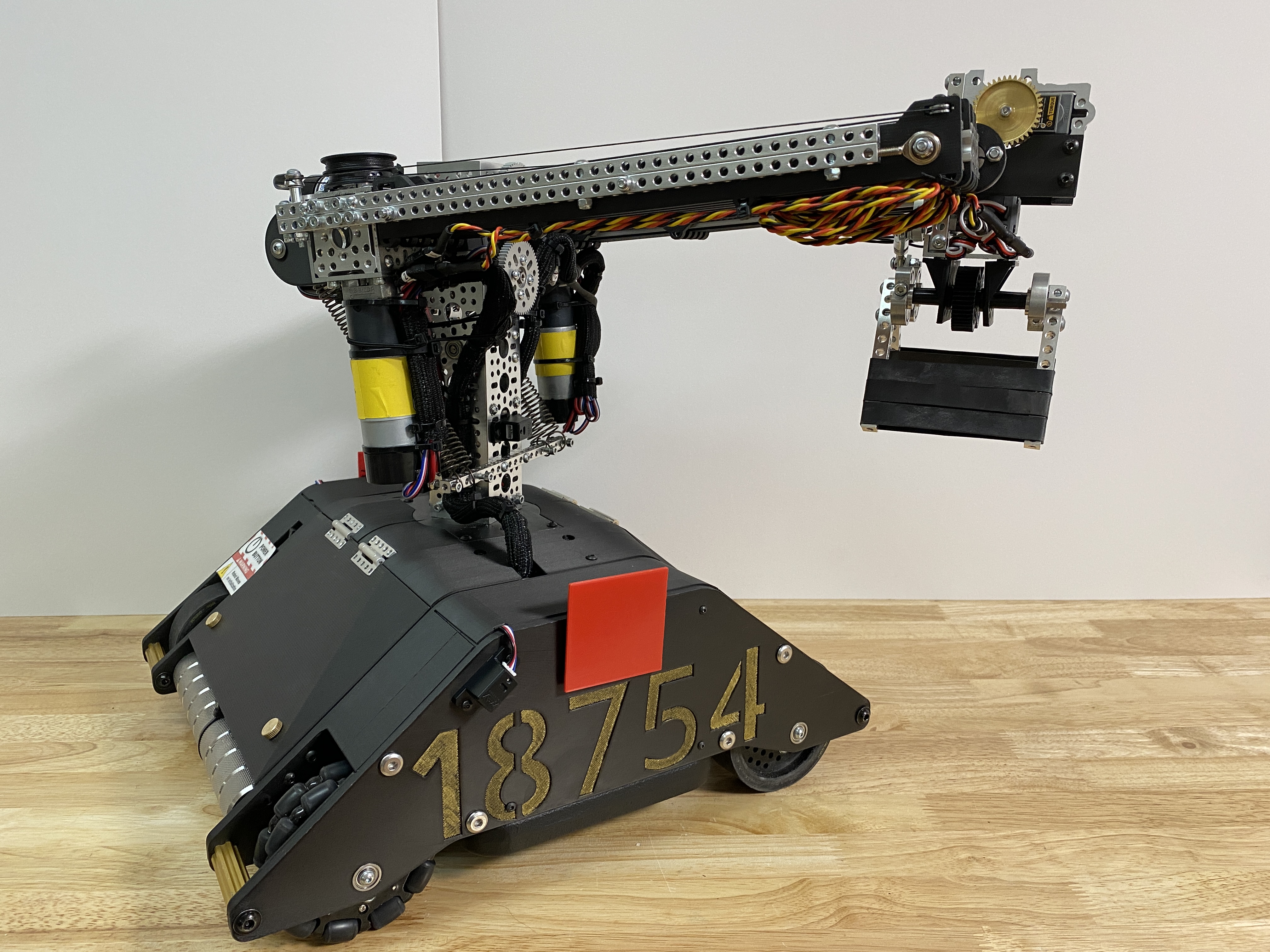

I led CAD and chassis design for my high school robotics team's (aka GNCE) 2022-23 PowerPlay robot, which was a 60+ lb robot featuring a 3D printed composite chassis with an extending, turreted arm that reached about 5 ft. That season I also worked to raise $100,000 for a state-of-the-art robotics facility in Weston, which won us the top judged award at States and the same in our division at Worlds, placing top four globally among >7000 teams.

Results & Impact

2022-2023 PowerPlay season highlights across competition outcomes and community growth.

Competition outcomes

- World Championship: Inspire Award (highest judged award, top four globally for Inspire); ranked 13th of 48 in our division.

- MA FTC State Championship: Inspire Award; semifinalist alliance captain; ranked 4th of 36; advanced to Worlds.

Community impact

- Raised $100,000 from nearly 600 families to build a GNCE Robotics and Engineering Lab supporting up to 3 FLL and 4 FTC teams.

- Reached 2,400+ people through demos, school events, and outreach.

- Started FTC Team 22489 (10 members) and 3 FIRST Lego League teams; mentored about 270 hours total (126 hrs FTC, 144 hrs FLL).

My Role & Ownership

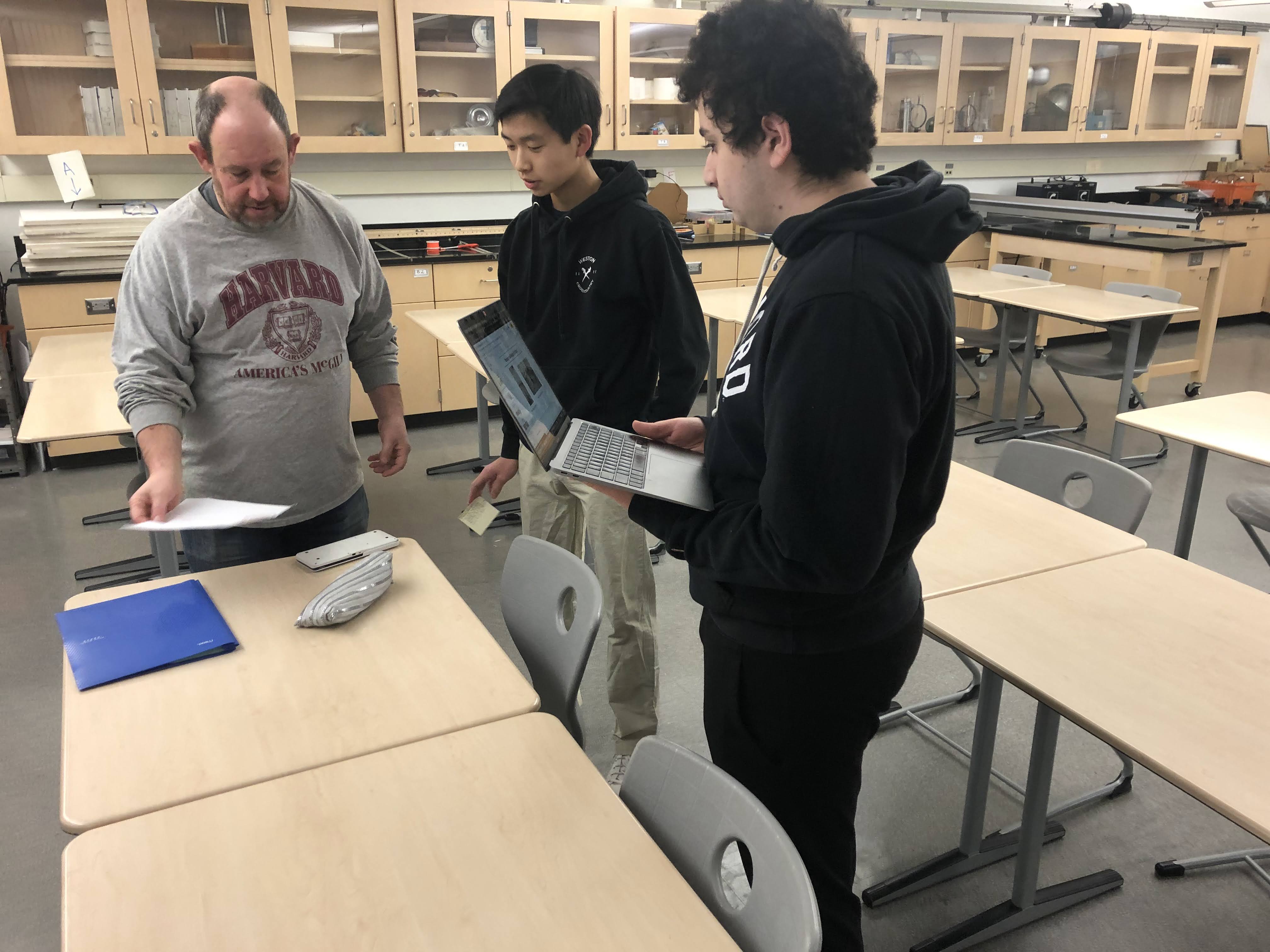

My areas of focus were CAD mechanical design, software, and documentation.

My role & ownership

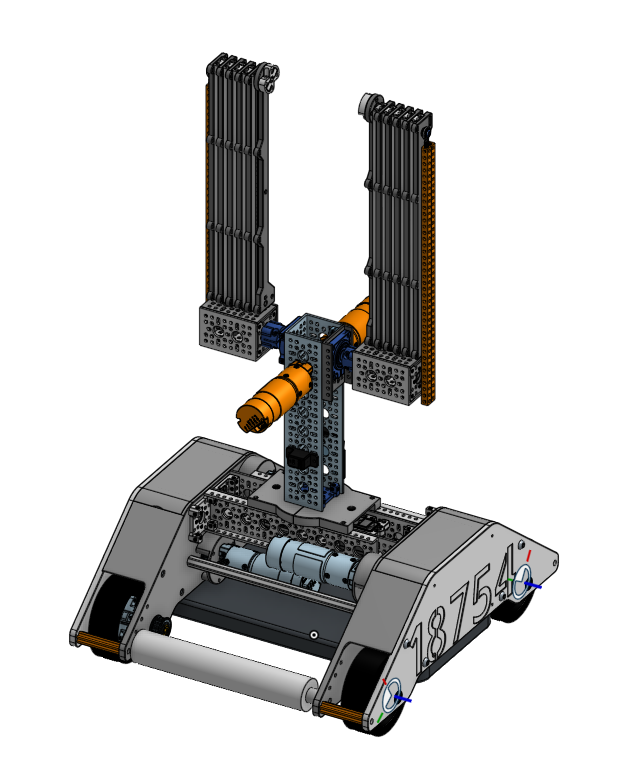

- CAD: Responsible for entire chassis design, CADed entire assembly for future visualization, designed claw.

- Software: Coded arm functionality and entire autonomous motion pathing algorithm.

- Documentation: Documented all work throughout the season via a 108-page engineering notebook (every meeting, design review, independent work session, etc...). Not a necessity, but significantly supported the team and impressed judges at the World Championship.

Collaborators: Sam Atefi, Finley Campbell, Theodore Dahl, Zack Gumbert, Arjun Jasuja, Zach Kano, Jonathan Lan, Rex Li, Jessica Shen, Ellie Tillman-Schwartz, Henry White

Design Highlights

Three focused highlights capture the core design decisions and the evidence behind them.

Arm assembly reach + precision

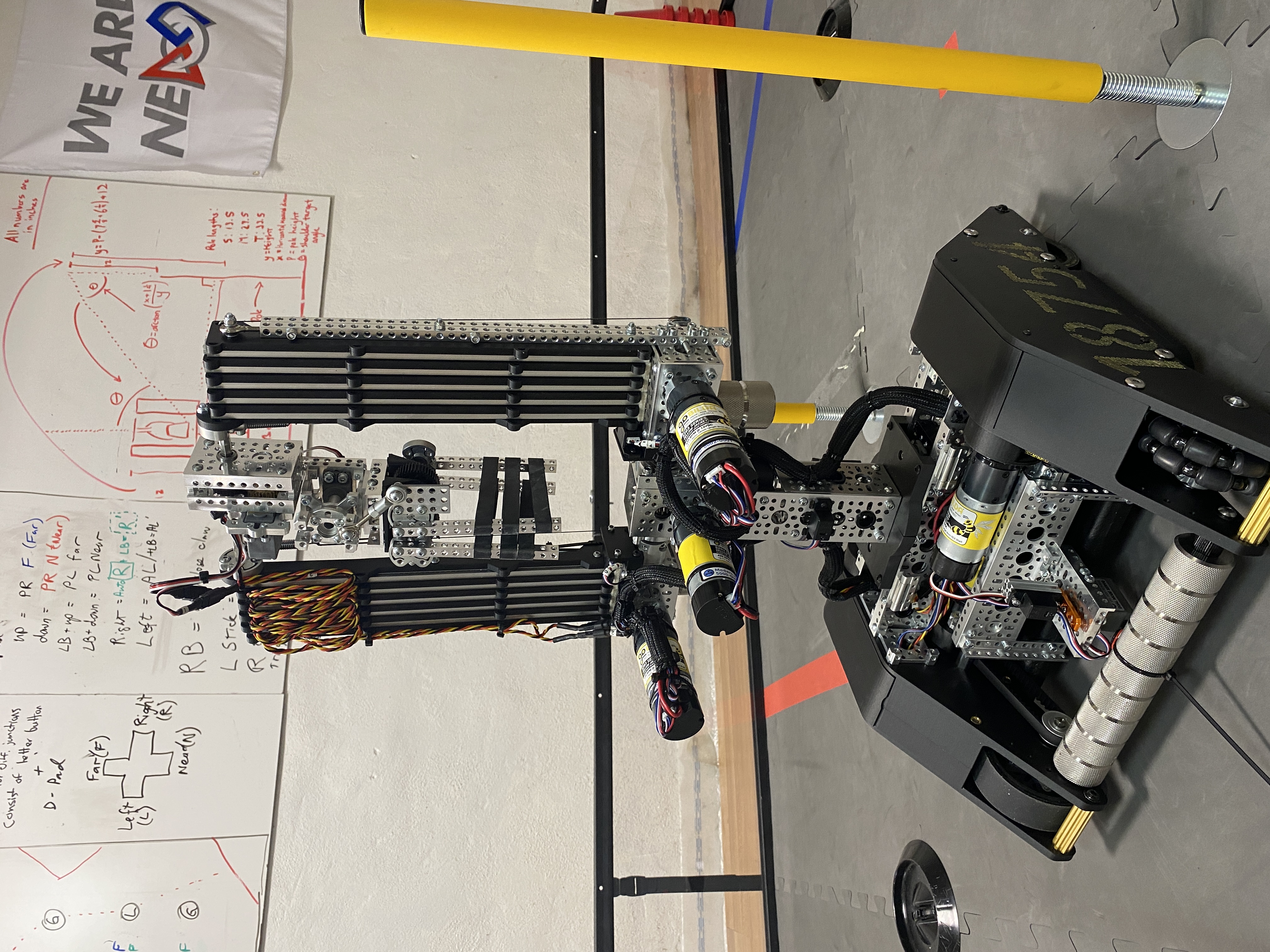

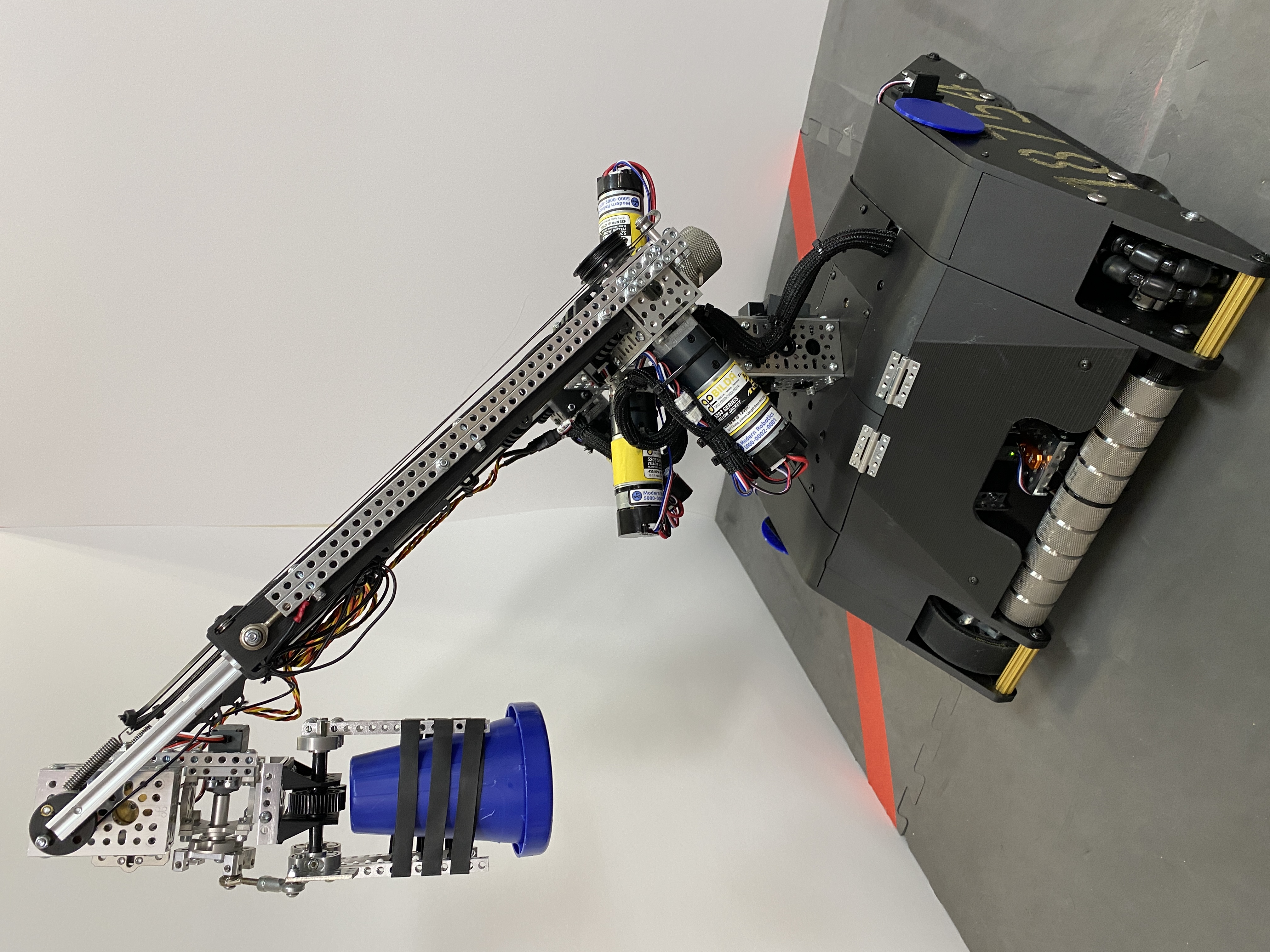

- What: turret + shoulder + dual slides + claw reaching about 5 ft.

- Why: aim to score without moving the chassis and reach as many scoring junctions.

- How: linear slides, double worm gear shoulder, an over-centered claw, and counter-springs.

- Evidence: full extension photo showing turreted reach plus close-up of dual slides and claw.

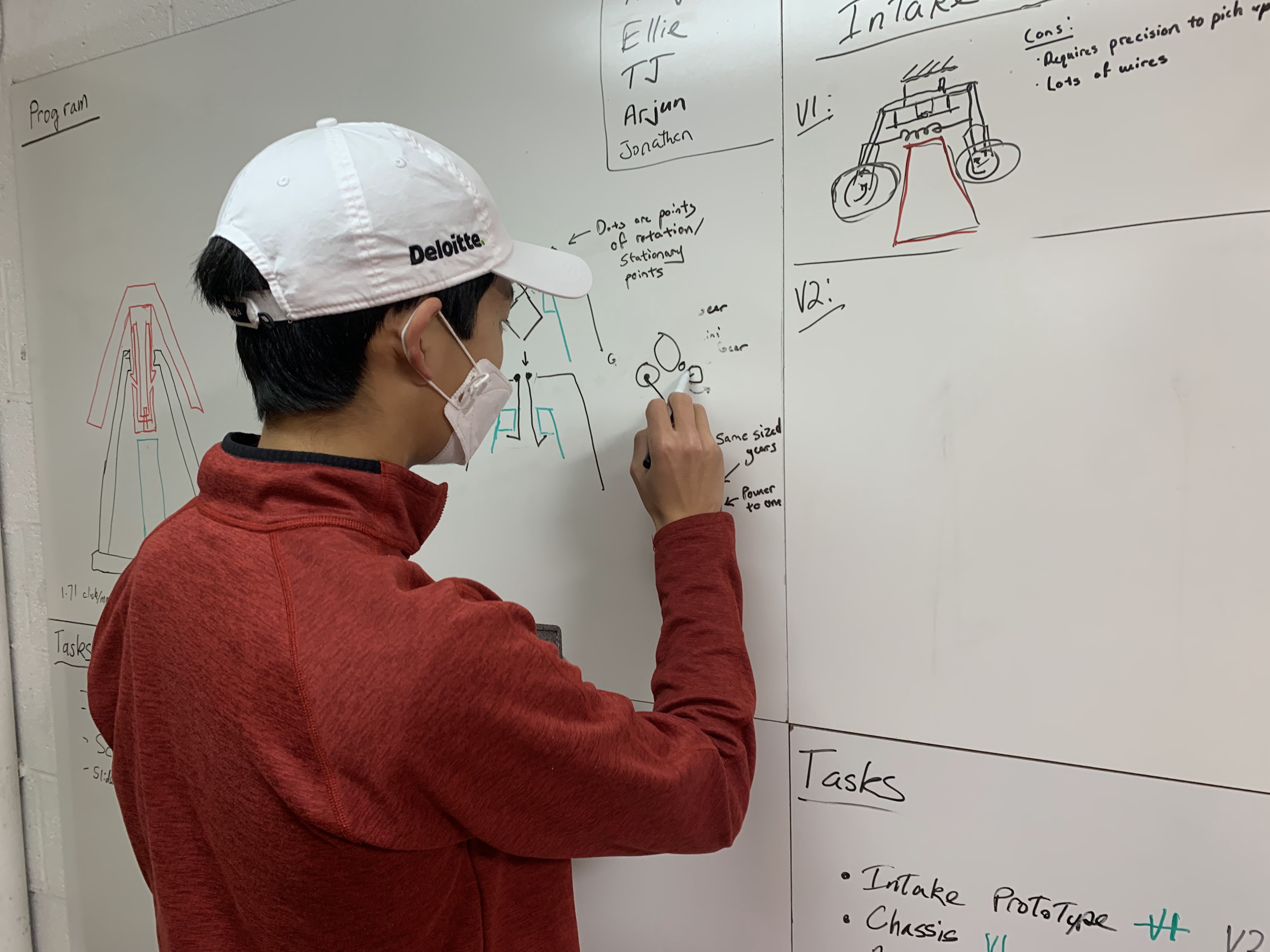

Intake evolution + reliability

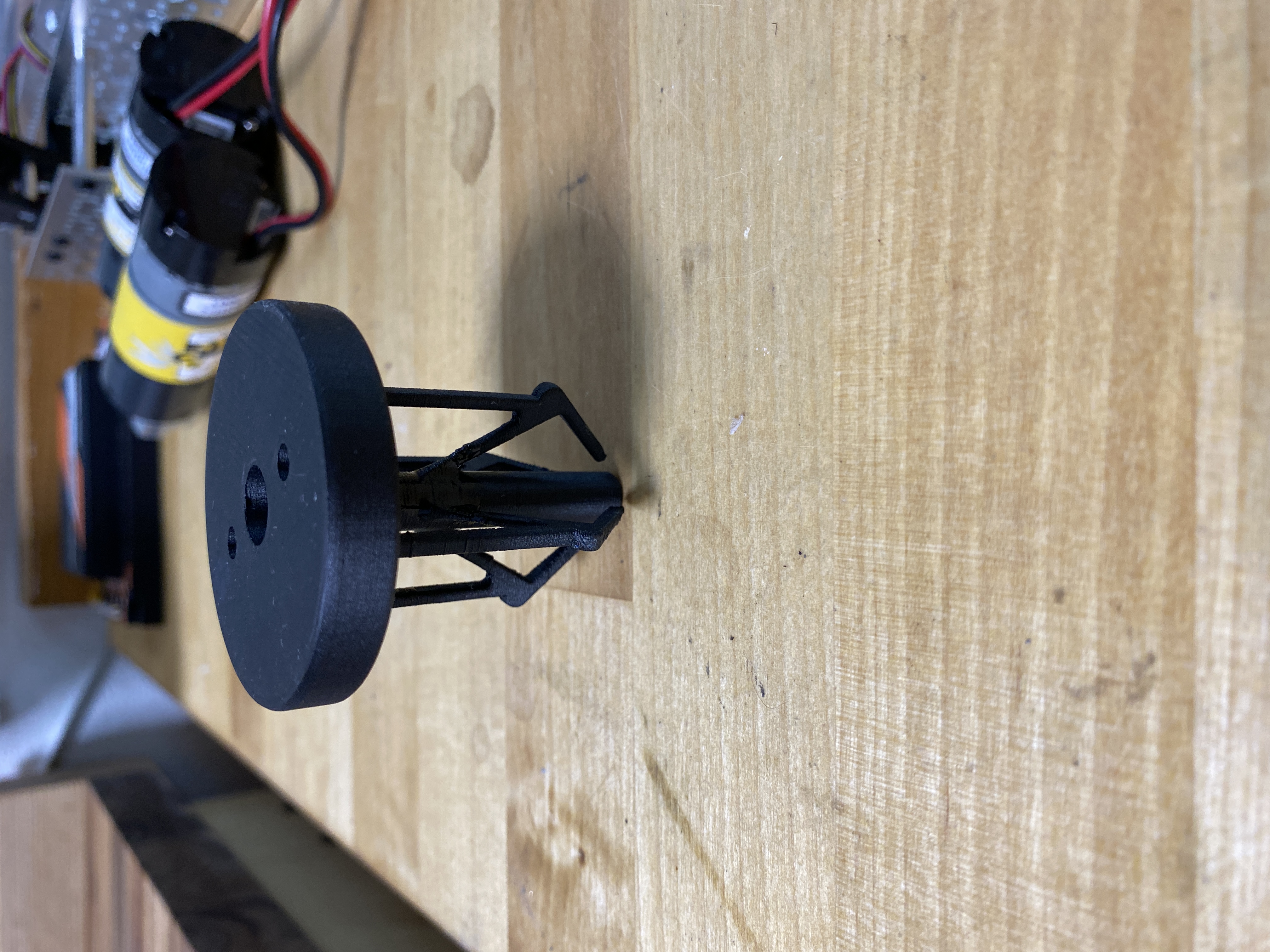

- What: claw intake optimized for stacked cones and fast service.

- Why: lower end-of-arm mass while keeping pickups reliable against stacked cones.

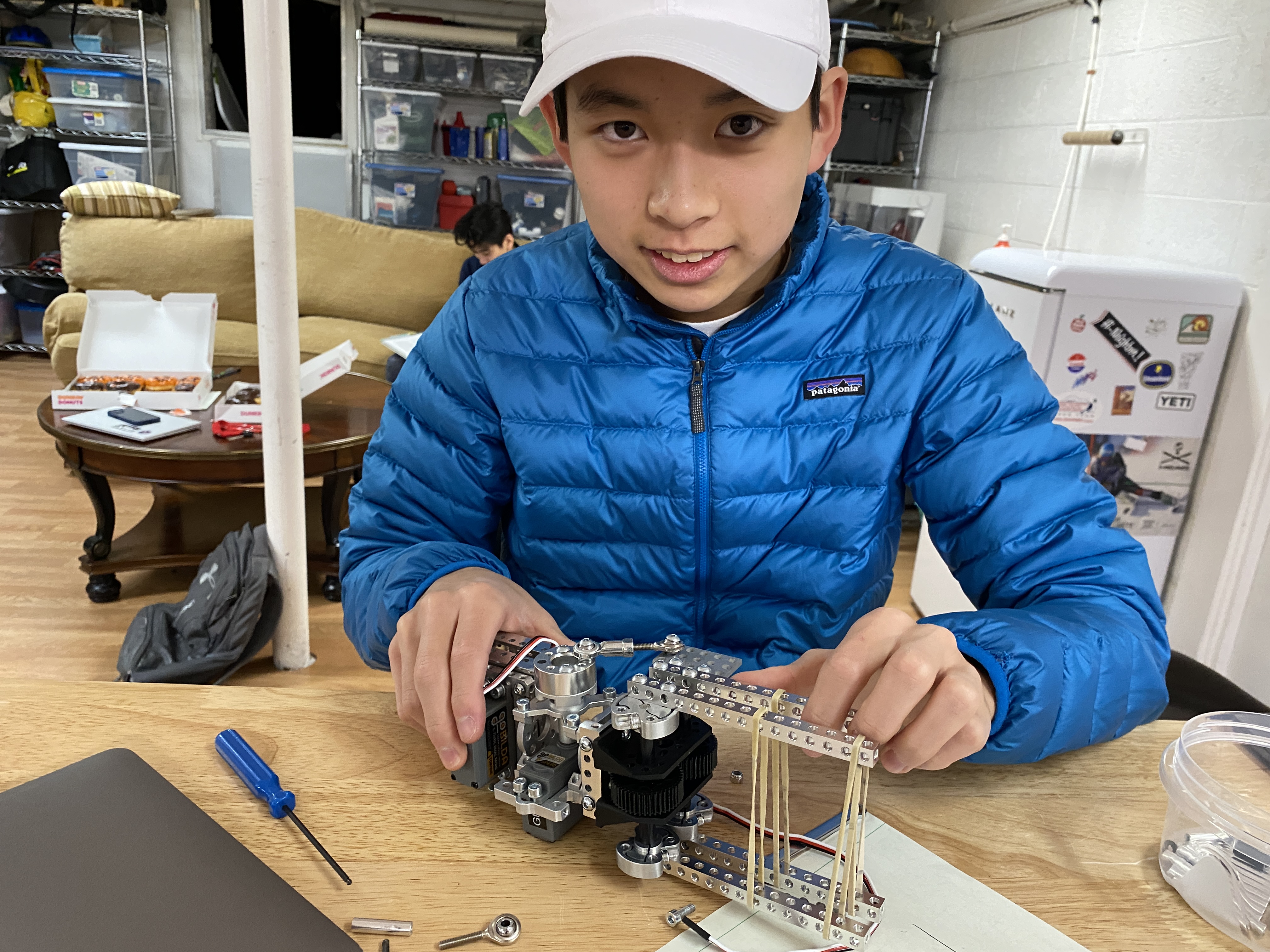

- How: tested sticky, octopus, and roller prototypes, then moved to an over-centered claw.

- Evidence: whiteboard concept sketches + photos of the first working claw build.

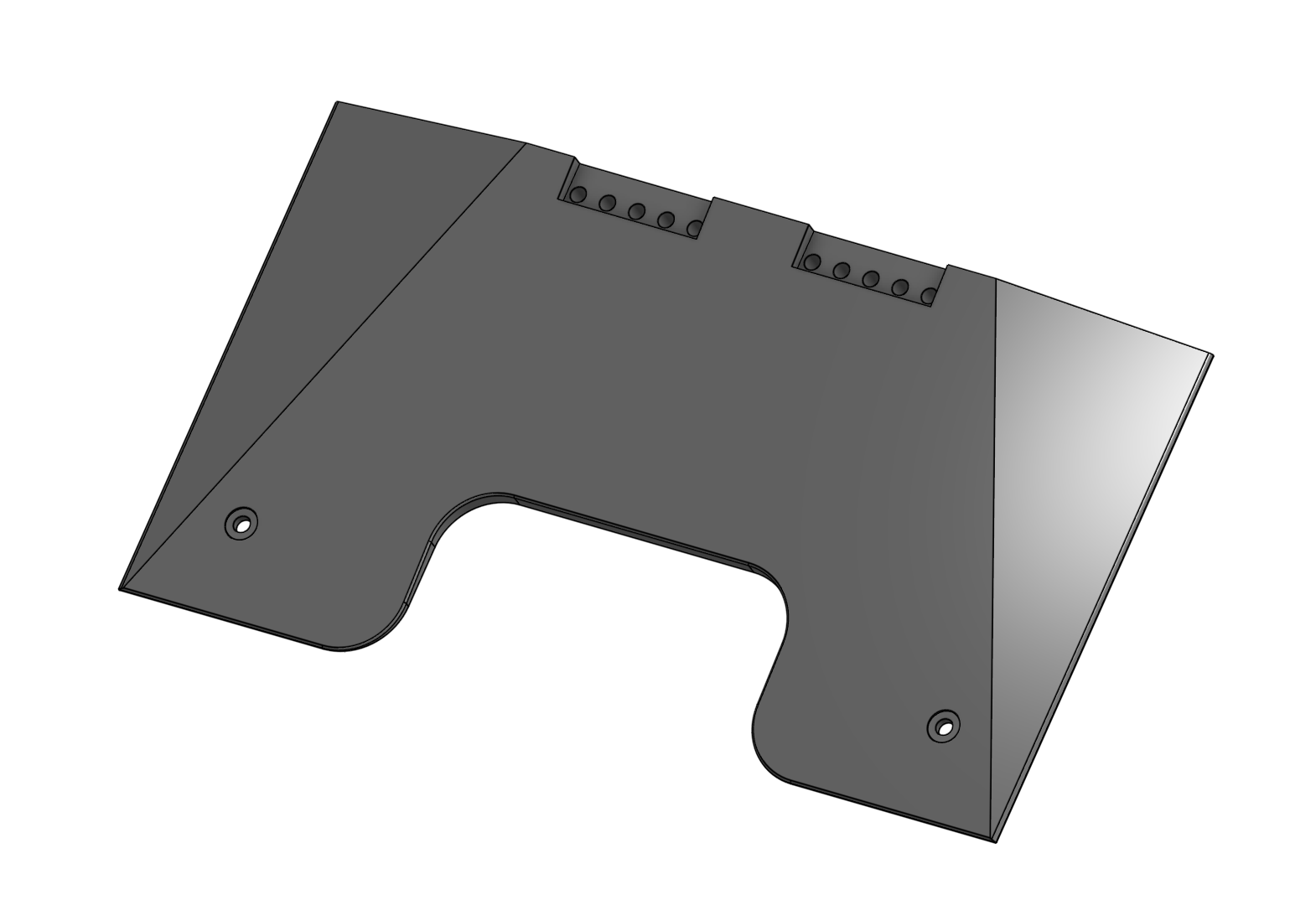

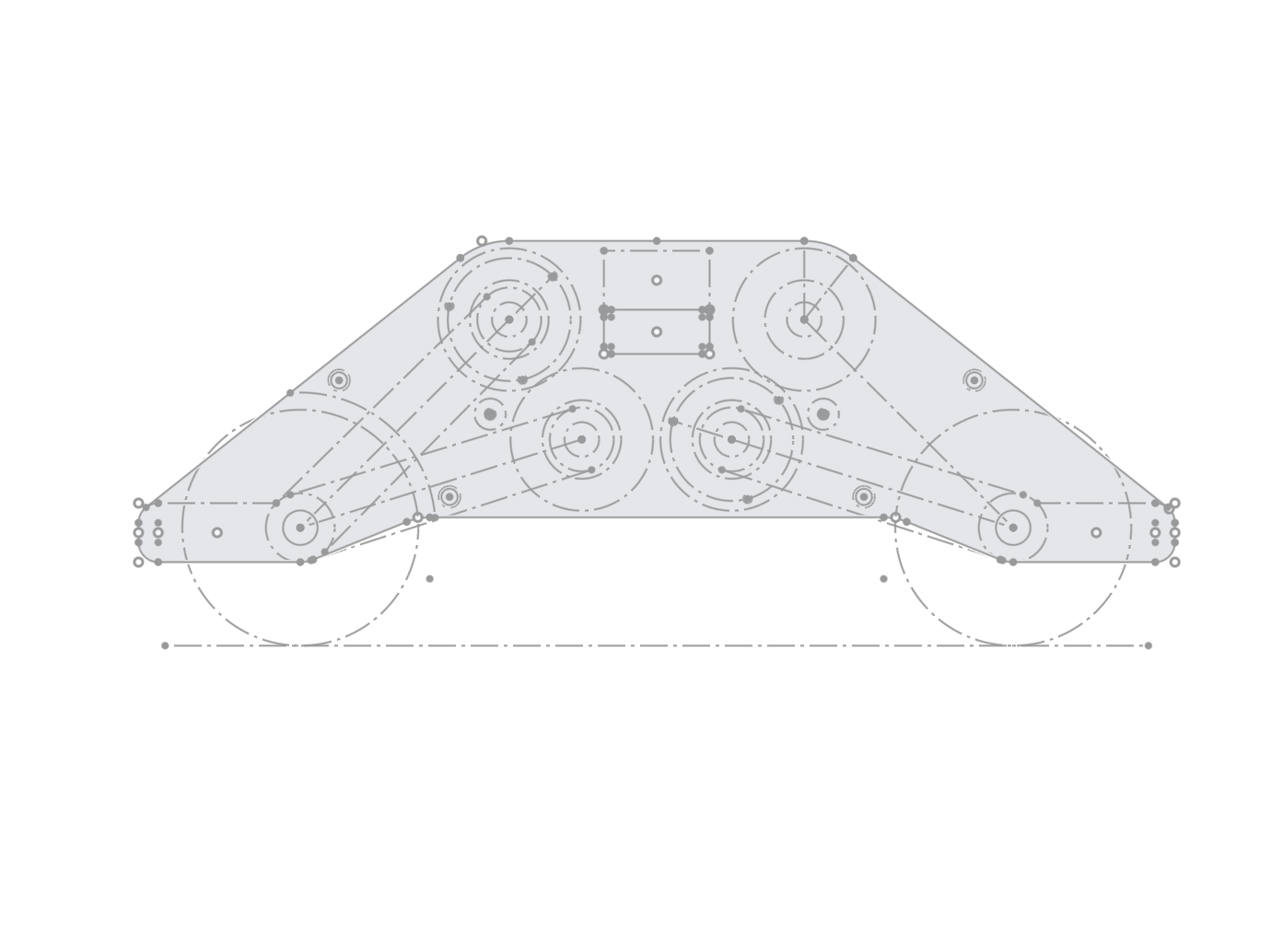

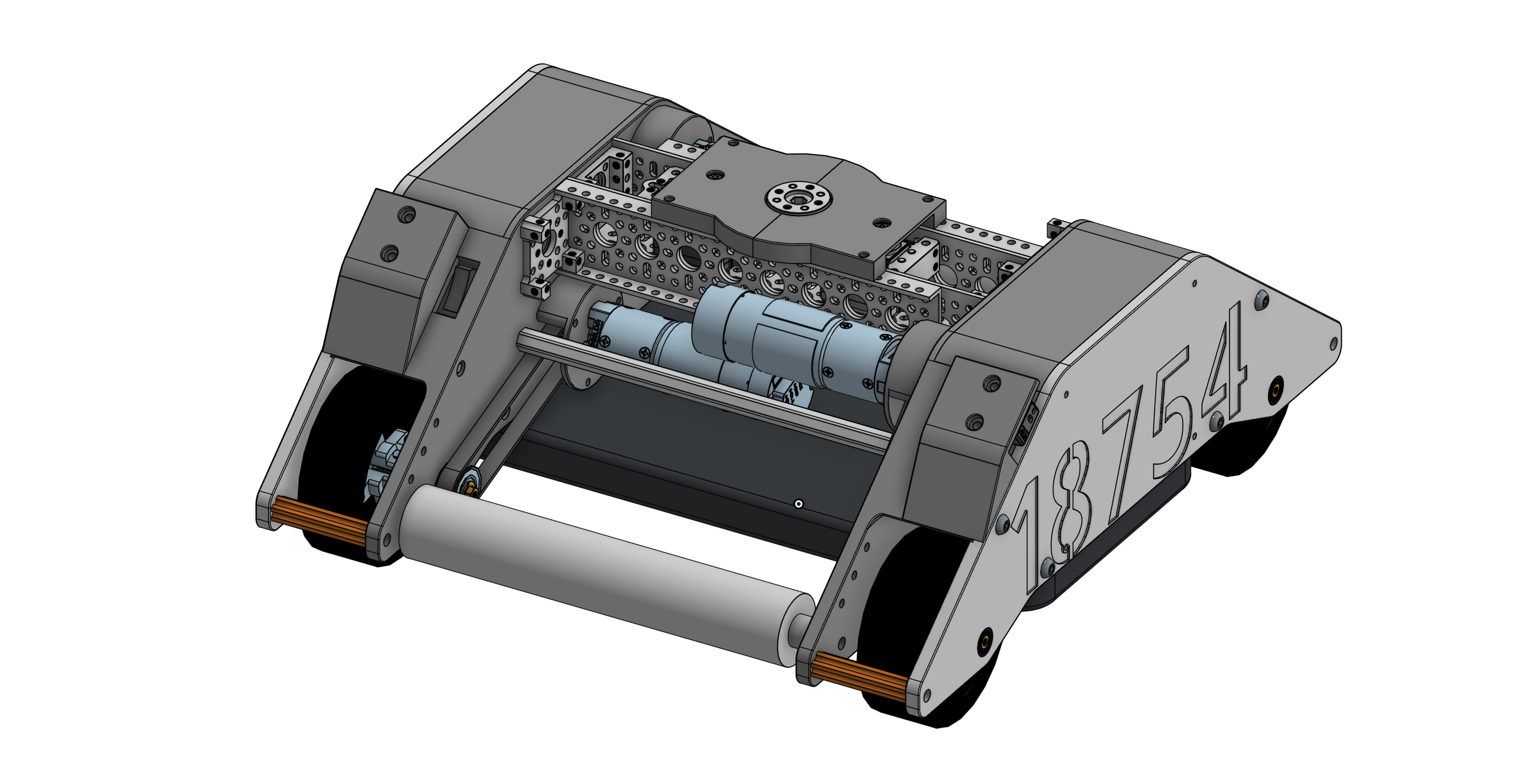

Chassis stability + industrial design

- What: custom 3D printed chassis with 20 lb ballast and protective covers.

- Why: lowers center of gravity, allows for narrow turning, and protects against collision displacements.

- How: innovative motor stacking geometry, mecanum wheels, and smooth-curved Onyx 3D prints.

- Evidence: chassis CAD render with ballast mount plus cover panel close-up.

Additional Robotics Media

Access to project documentation files that we were judged on for awards. Also access to our YouTube videos and a fun social photo-scroll.

Final Engineering Portfolio

Judging portfolio with design process, motor sizing, and subsystem breakdowns. Won various awards at the state and international levels.

View portfolioEngineering Notebook

Weekly build log covering outreach, CAD, testing, and competition notes. 108 pages long almost all written by me!

View notebookLessons Learned

Building this robot was the first time I seriously designed something using CAD, coded beyond basic libraries and classroom assignments, and found success at an international level. Innovative design-thinking made for one of the most unique robots on the field, which certainly means I will not be forgetting this tank of a robot anytime soon.

Moreover, raising $100,000 for a new robotics lab changed STEM education in Weston forever. In hindsight, this is the ultimate legacy of this season and it has made me realize what really matters in engineering is how great engineering improves human experiences and interaction.

Engineering Takeaways

- Documentation: Document any and everything from the engineering-design process. It helps in debugging, sharing knowledge, and improving future designs and you never know when it will prove useful.

- Iterate: Iterate, iterate, iterate. Every part of our final robot was the result of at least five iterations per part. The first few were not very successful but the final design resulted in a high performing robot.

- Collaboration Creates Stronger Results: FIRST as a whole stresses the importance of inter- and cross-team collaboration. Some of our robot's most innovative solutions were products of advice given to us by rival teams, such as the countersprings for our arm. These low-key design reviews go a long way.

Final robot build

Final robot build